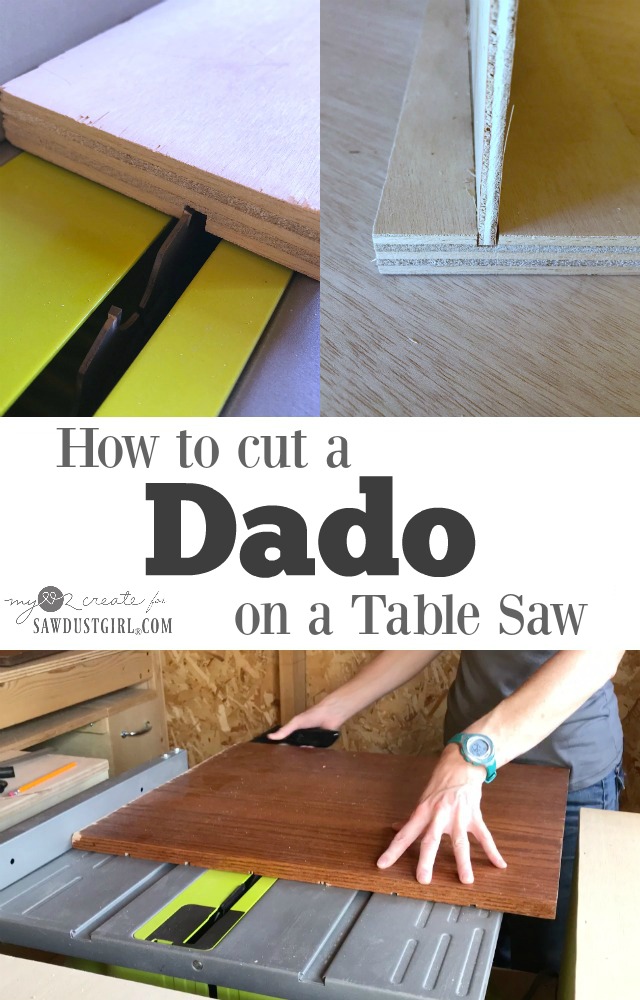

How to cut a Dado on a Table Saw

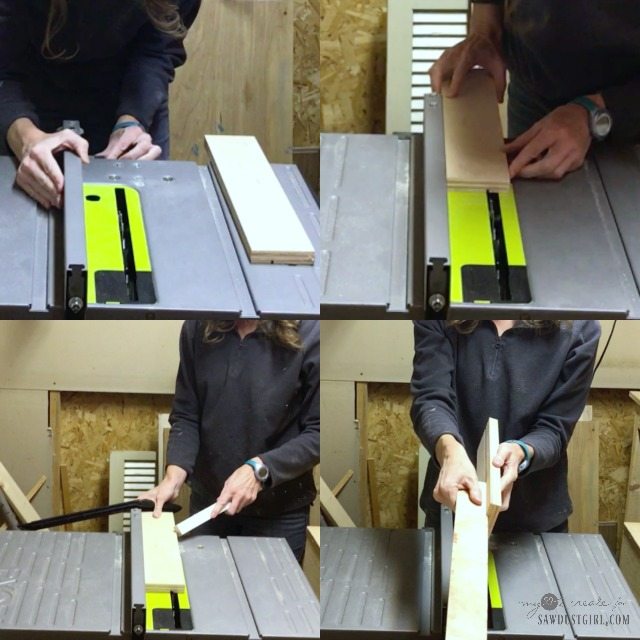

- Table saw

- Push Sticks

- Wood for the project you are making (can be any thickness)

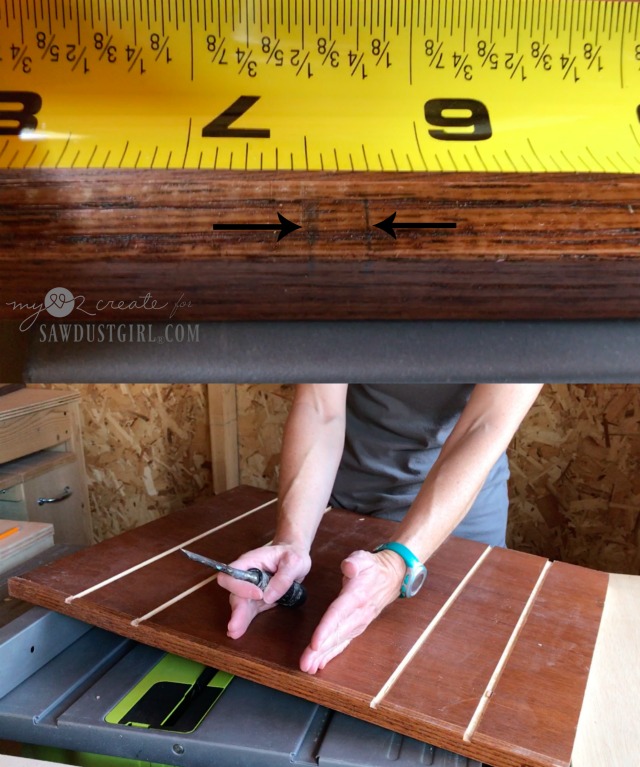

- Tape measure or combination square

- pencil

- Safety gear (glasses, ear/lung protection)

- Chisel, depending on how accurate your cuts are…you may not need it, but if you have some small slivers of wood then it is very helpful for removing them.

So what is a dado joint you ask? Well, first of all, let’s pronounce it correctly, maybe you already know, but I wasn’t sure. Sandra gave my the best way to remember…Dado rhymes with Play-dough! See?! Now you will never forget.

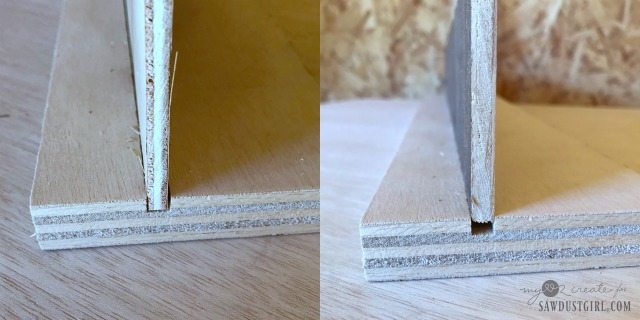

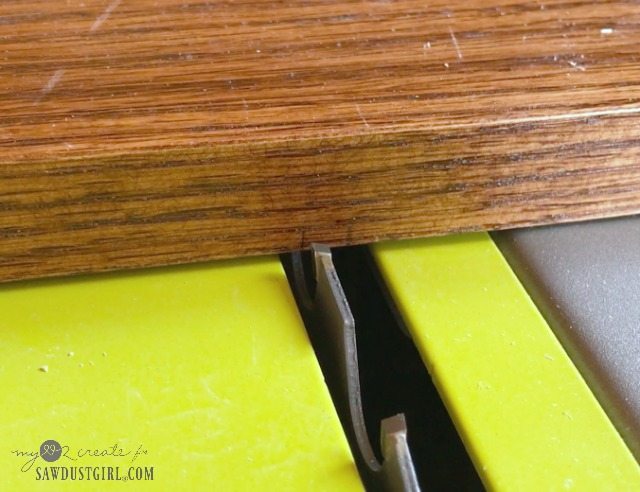

A dado joint is a slot or trench cut into wood where another piece of wood fits into. You can use these joints in a variety of ways, but a lot of times they are used for shelves to fit into the sides of a bookcase.

Barb says

Thank you. That was an excellent tutorial! My big fear (and I completely understand yours), is the miter saw. It terrifies me and I avoid using it at all costs.

Mindi Carwin says

Thank you Barb, I am so glad you enjoyed it! I totally understand about tools and fears, it is so important to be save and respect the tool. I hope someday you can overcome yours with the Miter saw…baby steps! I am still taking them on the table saw! 🙂

marvin says

Hi Ladies and whomever else.

A table saw just might be the most dangerous tool in the shop.

May I interject? I am not fond of a push stick. I take a scrap piece of wood, maybe 12″ long, and make two passes thru the saw. Look at your shoes in profile. See how the heel sticks down lower than the toe? I make a long cut maybe 1/2″ from the edge like the shoe sole about 3/4 the way along the wood, then

another cut to remove the long sole, leaving the heel to safely push the work piece thru the saw. I stand the push shoe against the fence and away I go. If you are making thin cuts, don’t worry about the push piece getting chewed up bit. When it’s shot, grab some scrap and make another. My current push shoe is about a year old and needs to be replaced.

Thank you, Sawdust girl – Another great and sorely needed post to your blog.

Y’all have a Merry Christmas and remember the true meaning of Christmas.

Mindi Carwin says

Thank you so much Marvin! I appreciate the tips, I can use all I can get with my limited experience on the table saw! Have a very Merry Christmas!

Lauren says

Thanks for this post– Im nervous about this tool as well, but feel encouraged after reading! Great tips and project!

marvin shelley - Master Sawdust Maker says

Hi Folks – Safety tips with power tools. I gave my Grandson – 23 YO – a table saw for his birthday and printed the safety list that I live by:

1) Never use any power tool when drinking alcohol – even one beer or glass of wine is a NO-NO!

2) Never get in a hurry. Under pressure – sit for 5 minutes and think about what you are about to do. Relax.

3) Never use a power tool when tired. Good way to make mistakes and get hurt.

4) Always try to keep those fingers at least 6″ away from a spinning blade. There are some exceptions.

5) Always use a push shoe or stick with the table saw. A crosscut sled is best.

6) Tell spouse and kids to never walk up behind you as a surprise when using power tools. When you jump, the work piece flies over your shoulder and hits them.

7) Never run plywood less than 1/4″ thick thru the table saw. Serious kick back will occur. I’ve only had 2 kick backs in 20 years. Both times was running 1/8″ plywood. Use the portable circle saw.

8) Use eye and ear equipment. I am almost deaf from not using cheap ear muffs. Harbor Freight has good ones for $2-$3. Hearing aides are $1,200 and up. I had to buy them last year. They also have face shields and goggles. An eye is a terrible thing to lose. All it takes is ONE splinter thrown off a spinning blade at 100+mph and you are blind in one eye – FOREVER!

I’ve been at this off and on for 20+ years and still have 8 fingers and 2 thumbs and 2 eyes, ears are shot! Play safe. Safe is cheap. Doctors and ERs are painful and expensive. Don’t be afraid of power tools. Just use them correctly.

marvin shelley - Master Sawdust Maker says

Free lumber at the saw mill – Your local saw mills piles up and burns the first cut on each of the 4 sides of the log. Meaning – there’s a lot of bark on the piece. Then they pile it up and burn it. WHAT?

When I visit the local saw mills to buy, I always ask if I can get a few sticks off the burn pile? There’s about 25-40% good useable lumber in every piece. You have to do some sawing when you get home to get rid of the trash, but, if you have time to do that, you can get lots of good lumber for free.

There’s lots of things you make with the trash with the bark still on it. Small boxes,candle holders, hat/coat racks, etc. Myself, I just do not have time to saw out the waste. One mill a few miles away has cedar bundles of the of the slabs. $20 a bundle all banded up nice and neat. Weighs about 1,700 pounds (hardwood weighs maybe 2,500 pounds) so you need a pretty

good trailer to haul it. It’s 8+ feet long. They will load it with their front end loader.

After you get the good stuff, stack and sticker for 6 months.

IF you GOOGLE SAWMILLS in your area, they will pop up. Or GOOGLE WOODMIZER and they will have a list of saw mill owners in your area.

Have fun! Be safe.

ANDREA says

Thanks for the correction on pronouncing dado. I refused to say it out loud, as I was never sure. Still working on conquering my fear of the table saw… but this gives me hope! On a side note, in Step 1, you refer to 1/4″ plywood; did you mean 1/2″?

Vic Rauch says

For making a dado to fit your piece of wood…

Cut off a piece of that wood to use against your rip fence. Set your rip fence where you want the “top” of your dado to be and then make that first pass for the “top” portion of the dado. Then put your piece of wood you cut first next to the rip fence (use the thickness of that piece) and make your second pass for your dado. If the dado needs to be wider than 1/4″, you now have the upper and lower sides of your dado cut. Now just move your rip fence 1/8″ in order to start ripping out the middle waste of material in your dado.